Product Description

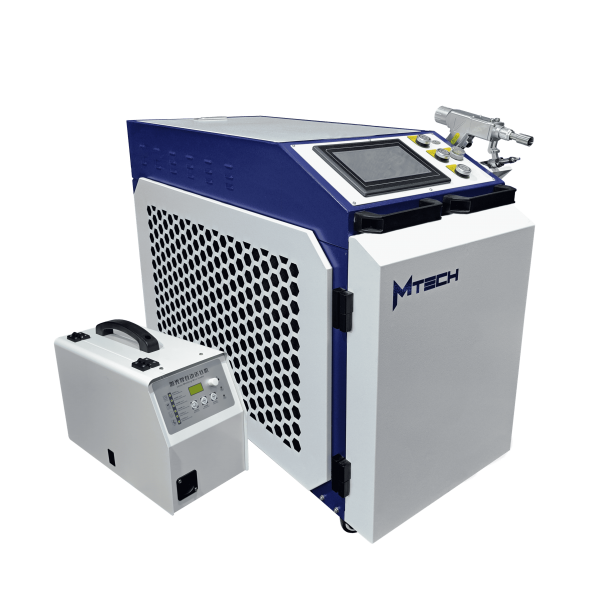

Лазерная сварка MTech FW

Manual laser welding machines with fiber-optic laser emitters are the latest development in the field of welding technologies, which replaced argon-arc welding. Used when welding metals such as stainless steel, iron, aluminum and other metals. They are characterized by a large depth of welding, strength of welds, suitable for welding of any complexity.

Installations for laser welding generate radiation in pulsed and continuous modes. The technology includes spot and seam welded joints. For suture, a continuous generation mode or pulsed with overlap is used, for a point, only pulsed. The point method gives minimal deformation and is used to connect products of small thickness. During seam welding, a deep welding channel is formed. The method is highly efficient in the processing of steels, titanium, copper and aluminum. A beam of high power density destroys surface oxide films and prevents the formation of new ones and does not require the use of protective inert gases. Welding of elements of small thickness is carried out with defocusing of the beam, this makes it possible to exclude through-burning of the product. To obtain a strong seam, the laser welding machine must be equipped with a radiation source of sufficient power.

Advantages

The weld seam is smooth and beautiful

There is no surface deformation, no subsequent grinding is required, there is no need for finishing the weld.

Weld uniformity

Achieved by uniform distribution of the point energy of the laser welding machine.

High welding speed

The speed of laser welding is 2-10 times faster than the speed of traditional welding.

Precise positioning

Precise positioning thanks to the red beam system.

Versatility

Flexible settings allow seam and spot welding.

Ease of operation

Flexible manual operation is easy to learn and does not require special training.

Technical parameters

| Model: | FW1500 |

| Laser power: | 1500 W |

| Laser pulse frequency: | 1-20 Hz |

| Minimum seam thickness | 0,1 mm |

| Laser source | Maxphotonics/Raycus/RECI |

| Pulse Width | 0,1-20 mc |

| Laser spot diameter | 0,1-4 mm |

| Cooling | Water |

| Water tank | built-in |

| Welding speed | 0-120 mm/sec |

| Welding sleeve length | 10 m |

| Focusing lens | f=50 mm |

| Size | 1200 х 800 х 800 мм |

| Weight | 150 kg |

| Life time | 100 000 hours |

| Supply | 380 V |

| Total power consumption | До 10 кВт |

| Ability to weld black/stainless steel | До 5 мм |

Лазерный источник Maxphotonics 4-го поколения

Новая серия волоконно-оптических лазеров Maxphotonics с одним модулем. Имеет повышенный КПД, что значительно увеличивает производительность и энергоэффективность работы. В третьем поколении источников значительно улучшено качество лазерного луча, надежность аппарата и устойчивость к суровым условиям окружающей среды. Обновление затронуло и систему передачи луча, что в итоге дает идеальное качество сварного шва. По характеристики цена качество Maxphotonics — бренд №1 не только в Китае, но и во всем мире.

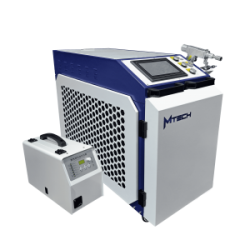

Laser sleeve with galvanometer

A laser welding sleeve with a galvanometer, in comparison with a conventional focusing head, requires 30% less laser power - this allows you to speed up the welding process and increase the life cycle of the laser emitter. The presence of a galvanometer motor improves the quality of the seam, prevents the formation of bubbles and significantly reduces the number of sparks.

Laser Welding Machine Controller

The welding machine control system comes with an English version of the software and is very easy to use. The user receives a device completely ready for operation, in which only the power of the laser beam and the pulse frequency will need to be adjusted. For example, for thin metals of 0.5-1 mm, the welding frequency is about 3000 Hz, and for thicker metals, in the region of 3-4 mm, it is 500-600 Hz.