CNC Routers

Showing all 17 results

-

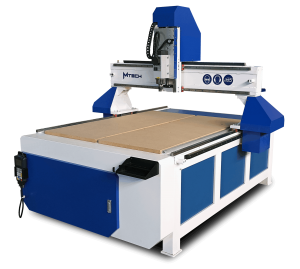

Фрезерно-гравировальный станок с ЧПУ MTech F1313 PRO

$8,800

378400 грнWorking area: 1300х1300x250 мм

Spindle power: от 3.5 кВт

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерно-гравировальный станок с ЧПУ MTech F1616 PRO

$9,200

395600 грнWorking area: 1600х1600x250 mm

Spindle power: от 3.5 кВт

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерно-гравировальный станок с ЧПУ MTech F2613 PRO

$9,900

425700 грнWorking area: 2600х1300x250 mm

Spindle power: от 3.5 кВт

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерно-гравировальный станок с ЧПУ MTech F2616 PRO

$10,700

460100 грнWorking area: 2600х1600x250 mm

Spindle power: от 3.5 кВт

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерно-гравировальный станок с ЧПУ MTech F3116 PRO

$11,500

494500 грнWorking area: 3100х1600x250 mm

Spindle power: от 3.5 кВт

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерно-гравировальный станок с ЧПУ MTech F3121 PRO

$12,000

516000 грнWorking area: 3100х2100x250 mm

Spindle power: от 3.5 кВт

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерно-гравировальный станок с ЧПУ MTech F4121 PRO

$12,900

554700 грнWorking area: 4100х2100x250 mm

Spindle power: от 3.5 кВт

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерно-гравировальный станок с ЧПУ MTech F8121 PRO

$17,600

756800 грнWorking area: 8100х2100x250 мм

Spindle power: от 3.5 кВт

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерный станок с автосменой инструмента MTech F3116 ATC

$22,400

963200 грнWorking area: 3100х1600x250 mm

Spindle power: 9 kW

Speed: до 25 м/мин

Moving mechanism: rack gear -

Фрезерный станок с автосменой инструмента MTech F3121 ATC

$22,700

976100 грнWorking area: 3100х2100x250 mm

Spindle power: 9 kW

Speed: до 25 м/мин

Moving mechanism: rack gear -

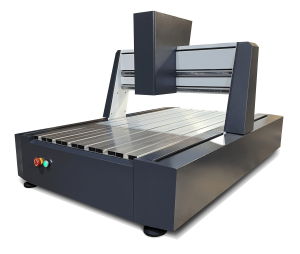

Настольный фрезер с ЧПУ MTech F1006 Lite

$3,000

129000 грнWorking area: 1000х600x240 mm

Spindle power: 2,2 kW

Speed: up to 15m/s

Moving mechanism: rack gear -

Фрезер с ЧПУ MTech F1006 HR

$4,000

172000 грнWorking area: 1000х600x240 mm

Spindle power: 2,2 kW

Speed: up to 15m/s

Moving mechanism: rack gear -

Фрезер с ЧПУ MTech F1210 HR

$4,600

197800 грнWorking area: 1200х1000x240 mm

Spindle power: 2,2 kW

Speed: 0-15 м/мин -

Фрезер с ЧПУ MTech F1212 HR

$4,900

210700 грнWorking area: 1200х1200x240 mm

Spindle power: 2,2 kW

Speed: 0-15 м/мин -

Фрезер с ЧПУ MTech F1515 HR

$5,800

249400 грнWorking area: 1550x1550x240 mm

Spindle power: 2,2 kW

Speed: up to 15m/s

Moving mechanism: rack gear -

Фрезер с ЧПУ MTech F2112 HR

$6,000

258000 грнWorking area: 2100х1200x240 mm

Spindle power: 2,2 kW

Speed: up to 15m/s

Moving mechanism: rack gear -

Фрезер с ЧПУ MTech F2115 HR

$6,400

275200 грнWorking area: 2100х1500x240 mm Spindle power: 2,2 kW Speed: up to 15m/s

Moving mechanism: rack gear

Main parameters of CNC Routers

To choose the CNC Router machine that meets all your requirements, pay attention to the following points: Today, CNC Routers can work in almost any large or small enterprise, regardless of its field of activity. The choice of such a machine is a rather complicated process that requires attention to the settings of the machine, its dimensions, materials that will be processed and many other factors.

- Workpiece size. Determine the largest dimensions of the items and materials you are going to process. So you decide the size of the working surface of the milling machine. To make your work as productive as possible, you need to avoid reconfiguring and changing processing programs. If you do a complete machining of a part in one go, you don't have to worry about the quality of the parts.

- Machine structure. When choosing a CNC machine, pay your attention to the portal. The cast iron surface must be solid and vibration resistant. If you are considering an aluminum gantry milling machine, it is worth remembering that it is less durable and can negatively affect the quality of your products. It is also important to pay attention to the dimensions of the spindle travel within the Z axis.

- The spindle of a 3D CNC wood milling machine is one of the most expensive elements of the machine. If you opted for a liquid cooling system, pay attention to the brand of the manufacturer. Choose proven brands with a guarantee of quality and service support. Leave a margin, taking into account the power of the spindle, to withstand all loads.

- The type of gantry movement motor affects the accuracy and speed of work. When choosing between stepper motors and servo motors, choose the latter as they do not skip "steps" in the production process and improve the quality of material processing.

- The most reliable controller today is Syntec (manufacturer - Taiwan). When using it, you no longer need to connect a computer, and you will immediately appreciate its benefits.

- Number of tools. Before purchasing a CNC milling machine, determine how many tools you will need for a full-fledged job. If the number exceeds 3, then it is worth paying attention to the automatic tool change system in order to save time and resources.

- Pay attention to the software of the machine you are about to buy. For example, outdated programs like UcanCam are no longer very convenient to use for processing 3D parts. If you are not an expert in English, ask about the presence of the Russian interface in the program.

The CNC router is perfect solution for industrial woodworking. Ease of use of this equipment follows from a well-thought-out design and a set of electronics, necessary for management.

Features of MTech’s CNC routers:

Solid all-welded steel base

As usual, the frame of the machine is made of 3 mm rectangular steel tubes with cross-sections to ensure a high degree of stability of the machine’s structure, the possibility to withstands static and dynamic loads. Machine’s bed also promotes absorption of vibration during it’s operations.

Steel portal

A massive portal is made of steel pipes with thick walls, processed in form of rectangular section. The thickness of this part reaches 8 mm (in places of linkig, the cross-section reaches 16 millimeters), which allows to guarantee the highest degree of rigidity of easel portal, resistance to static and dynamic loads. Through portal machining in one go in CNC machining centers, the machine achieves significant geometric accuracy. This type of construction allows to get an original workpiece of the highest quality, regardless of the material used.

Linear guides

Thanks to significantly improved stability of guide rails, high definition of gantry and spindle movements along X, Y, Z - axes is achieved. Linear guides contribute to long-term work of machine without loss of accuracy during operation.

Rail grease system

Cartridge greasing of guides ensures uptime of guides on X-Y-Z travel axes. Amount of grease is dosed and depends on size of the machine and intensity of work on it. Bearings can withstand work up to 5,000 kilometers without additional maintenance.

Reinforced spindle platform

Improvement and strengthening of spindle pad is necessary in order to

reduce vibration during materisls machining. To do this, the manufacturer

increases the cross-section of the cast structure, sets more powerful guides

and includes additional stiffeners. In addition to reducing vibration level,

such an upgrade significantly increases material processing speed.

Spindles have a high rotation frequency (up to 24 thousand rpm). With

a power of 3 kW machine is capable of processing not only wood,

chipboard and MDF, but also acrylic glass and plastic, as well as other

materials. There is cooling system installed under the spindles.

The spindles have a high rotational speed (up to 24 thousand revolutions per minute). With a power of 3 kW, the machine is able to process not only wood, chipboard and MDF, but also acrylic glass and plastic, as well as other materials. A cooling system is installed under the spindles.

Calibration sensor and tool length measurement

This element is used to automatically adjust the length of the tool. It also allows easily and quickly enter table surface data (Z = 0) and workpiece height at the start of the workflow. Sensor increases operational safety and protection of desktop surface.

Four axial displacement stepper motors

Stepper motor is an electromechanical device that converts impulse into mechanical movement. Installed on all nodes of movement along X, Y, Z - axes, it guarantees the exact placement of the spindle, depending on set basic program.

What are the advantageous differences between a stepper motor and synchronous motors?

- First, angle of rotor rotation depends on number of electrical impulses.

- Secondly, stepper motors provide the ability of quick stop, reversing or starting.

- Thirdly, stepper motors price is significantly lower than for synchronous.

- Fourth, thanks to stepper motor, positioning can be done without feedback sensor.

Combined vacuum table with "T" – slots

The working area of CNC router is a dualism of a vacuum and aluminum tables with T - grooves. This allows to achieve high flexibility and provides a wide choice in the method of fixing the workpieces. So, the fastening of the workpiece can be done both by using a vacuum table or with a mechanical clamp. This variation allows to significantly reduce electricity consumption in conditions of part processing without frequent workpiece changes or when overtaking workpieces around the perimeter. Thanks to the division of the vacuum table into four zones installation and fastening of workpieces of various sizes is not a problem. In addition to the vacuum table, manufacturer also uses a vacuum pump. This oil-free, lamellar-rotor element guarantees reliable fastening of workpieces and parts, as well as long-term work of the CNC machine.

Pneumatic stops, base blanks

Pneumatic stops simplify work with the machine, primarily thanks to that that the workpiece can be easily and as accurately as possible placed on the working area of a table. As a result, productivity increases by 10-15%. At the same time, spindle’s work don’t feel an additional load, since the stops move only at the right time, being controlled by adjustment pedal.

Control cabinet

This construction, without a doubt, can be called the main element of a CNC router. The control cabinet is located in a separate unit to isolation from side effects such as vibration and overheating. Ergonomics maintenance and ease of use are achieved, in including, thanks to the precise placement of components and various kinds of connections.

Programmable Logic Controllers (PLC)

PLC is a device, which function is collection, transformation, processing, information storege and developing of control commands. This is part of an industrial controller, specialized device, that is used to automate technological process.

Frequencies converter

Designed to change the frequencies of electrical voltage. This device allows to convert mains three-phase or single-phase alternating current from 50-60 Hz frequency to frequency up to 800 Hz. Frequency converter provides alternating current motor control both synchronous and asynchronous.

CNC rack cooling system

In order to protect the machine from overheating and thereby increase its service life, Mtech company installs on milling machines forced cooling system for CNC racks (front and back). These extra precautions allow milling machines to operate even at high temperatures and intensive use.

X and Y shielding cable guards

They guarantee protection of the cable from external factors (for

example, protects against mechanical damage due to the fall of the overall

trim). Cablelayers perform two main functions:

- improve safety indicators at the workshop;

- extend the service life of the milling machine.

- improve safety performance in the workplace;

- extend the life of the milling machine.

Aspiration unit (AU)

Waste is an integral part of wood processing. To solve the problem of the most effective removal of unnecessary debris after machine operations, Mtech uses aspiration installations (from aspiration - dedusting ventilation). Aspiration equipment works as a vacuum cleaner, but using a vacuum air technique.

There are two types of aspiration systems - industrial and compact (local). The former are used to ventilate the entire workshop (that is, setting them makes sense at large production facilities). Mobile or local aspiration devices have several significant advantages over industrial ones. First of all, of course, it's installation cost. Saving on the mobile version of the vacuum cleaner allows to increase the efficiency of the main invested capital. At the same time, savings are not only at the procurement stage, but also during operation. Secondly, mobile AUs work on "local" level, servicing a specific machine, improving the quality of waste disposal.

NC-Studio control system

CNC wood routers often work on the basis of the NC Studio control system.

This system differs from other similar ones:

- simple, easy to use interface. The undoubted advantage is the ability to use a standard computer keyboard and mouse;

- easy assimilation process;

- function of virtual simulation of programs;

- protection from inconsistent change of tinctures;

- cooperation with other modern modeling programs such as ArtCam and Type 3.

In addition to NC Studio control, Mtech offers ArtSoft Mach 3 software to customers. These two control systems have a lot in common: from the purpose (namely, control of CNC machines) to installation. The Mach 3 has been designed for both mass production and amateur operators. Thanks to this gradation, Mach 3 has become the most used software for machine tools. Having mastered it, you will be able to work not only on milling machines, but also successfully use lathes, plasma cutters, engraving equipment, etc.

Key Features of ArtSoft Mach 3:

- interface reconfiguration function (i.e. the ability to make the interface convenient for each specific operator);

control is possible from 3-6 coordinates; - import files in DXF, BMP, JPG and HPGL formats;

- spindle speed control;

- video surveillance of the workpiece processing process through a special window;

- the ability to work with the help of the Touch screen;

- using a manual pulse generator.

Additional features:

Industrial Voltage Stabilizer

For maximum safety, as well as to avoid interruptions in work, the manufacturer installs industrial voltage stabilizers on CNC machines. The stabilizers used by the manufacturer compare favorably with their price range, build quality and reliability in production.

The device used by Mtech differs from analog stabilizers:

- Improved body design;

- Advanced cooling single-phase voltage regulator;

- Optimized circuit design;

- Additional load protection due to network surges;

- Overheat protection.

Software

On CNC milling machines, Mtech uses the ArtCam Pro software package. This software has gained well-deserved fame due to the use of a unique set of modeling and material processing tools. This allows you to produce 2D and 3D products in the shortest possible time, taking as a basis a variety of sources - photographs (including digitized ones), scanned pictures and sketches.

ArtCAM Pro not only provides you with the necessary tools, but also powerful support from the developer. This includes: free tutorials and video tutorials, online support, multiple forums, and access to the latest software.

ArtCAM Pro not only provides you with the necessary tools, but also powerful support from the developer. This includes: free tutorials and video tutorials, online support, multiple forums, and access to the latest software.

Buying a CNC milling machine means investing in production and gaining the opportunity to receive a stable income from orders for the manufacture of a wide variety of products. The main advantage of milling machines is their versatility and flexibility in use. Thus, any kind of goods - from small wooden souvenirs to factory-made wooden furniture - can be the result of working on this equipment. The Mtech company sells machine tools throughout Ukraine - Kyiv, Odessa, Dnepropetrovsk, Lviv, Kharkov and other cities.

Where can a CNC Router be used?

CNC milling machines are used in the machining of materials of flat and spatial surfaces, engraving, for power milling and cutting, 3D modeling, and other purposes. Among the processed materials are wood, plastic, metal, acrylic, composite, jewelry, marble, stone and many others. Some machines process several parts at the same time, which helps to increase the efficiency of production. Ordering a 3D CNC milling machine means providing your company with reliable equipment with excellent accuracy of operations performed.

Please contact us and we will help you choose a machine according to the requirements of your production. Our experts will take into account all your requirements and provide you with high quality equipment with the parts and functions you need.

You can buy a CNC wood router from MTech. We offer fast delivery and high quality equipment. Our machines are made to the highest quality standards and will serve you for many years. We deliver milling machines in Kyiv and EU.