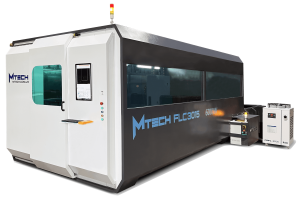

Fiber laser machines

Showing all 9 results

MTech offers the supply of equipment for laser cutting of metal. This equipment is indispensable in the metalworking industry, in particular, when cutting sheet metal. With it, you can process steel, stainless steel, as well as non-ferrous metals.

The production of metal structures begins with procurement operations. The quality of the finished product is directly related to the quality of the semi-finished products made for it.

In some industries, gas cutting is still used, somewhere mechanical methods are used - guillotines or mechanical saws, who use more modern plasma installations. But individual metal product manufacturers are increasingly studying metal laser machines and are considering buying a fiber optic laser machine to perform metal blanking operations.

Let's talk in more detail what it is, what are the advantages and difficulties in using this equipment.

The principle of operation of a fiber optic laser machine

The operation of such equipment is based on the fact that a laser beam that carries a certain amount of energy is sufficient to penetrate into the body of the workpiece, for example, into a sheet of metal. Under the thermal action of the beam, the metal passes the melting point, then boiling after that, it takes on a gaseous state and simply evaporates. At the same time, there are no drops of molten metal or sagging along the edges of the obtained parts. For the most part, evaporative laser cutting is used to process thin sheet material. For example, elements of a chimney or decorations on the facade of a building.

General characteristics

Laser metal cutting equipment can be used to process sheet metal of different thicknesses. In particular, the machines produced by our company are capable of working with metal with a thickness of 3 to 26 mm. Of course, the thickness of the processed material depends on its brand and the power of the laser machine.

With the power of the laser emitter, it is possible to cut a sheet of ferrous metal up to 12 mm thick, and aluminum up to 6 mm.

The main difference of laser machines of our production is their frame.

For its manufacture, sheet carbon steel with a thickness of 10 - 12 mm was used. All welding work is carried out in a shielding gas environment. This, in turn, ensures high quality permanent connections.

In addition, the portal guides are installed at an angle to the bed. This design solution allows to reduce the load on the bearings with the help of which the portal moves with the laser cutting head installed on it.

Equipment Advantages

The main advantage of laser metal cutting machines is their accuracy.

The side play during operation lies within 0.03 mm. This allows you to adjust the production of blanks of appropriate accuracy. That is, they do not require additional mechanical processing.

Due to the fact that the diameter of the laser beam is constant, it avoids the slopes that are formed during plasma cutting. This is especially noticeable to the naked eye after the metal is processed with a large thickness.

The use of laser machines for cutting metal can significantly save on the purchase of material - with a properly planned sheet cutting, the amount of waste can be reduced to almost zero. This is due to the high accuracy of laser equipment for metal cutting, as already noted, the cutting accuracy is 0.03 mm.

Equipment of this type is capable of cutting metal with a laser head speed of 80 m/min.

Control

The machines manufactured by our company are equipped with the CytCup software package focused on working with equipment for laser cutting of metal. This package allows you not only to perform the cutting process itself, but also its configuration, modeling, etc.

This software package allows you to process drawings imported from programs such as AutoCad, SW and many others. That is, it is enough to create a drawing of a part in one of the CAD packages and translate it into CytCup.

How to buy

You can buy a laser machine for metal in Ukraine by contacting our company. We produce laser cutting machines for metal, which provide high-quality cutting of sheet material.