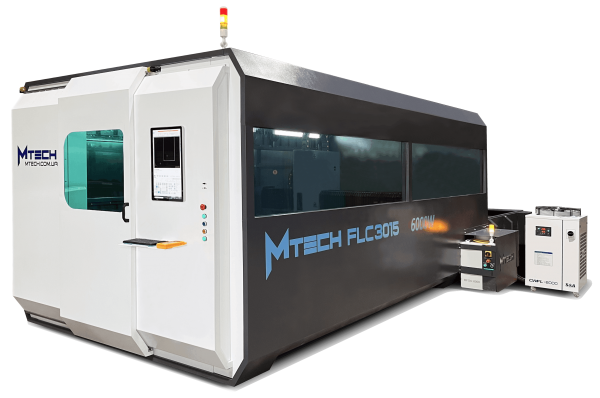

Product Description

MTech FLE3015 fiber laser

Metal laser machine MTech FLE3015 is a closed-type laser cutting kit. The FLE series is a complete analogue metal laser cutting machines MTech FL with the addition of a protective casing with windows of their protective glass. Due to this, it fully complies with European CE and EHS standards.

Cutting capabilities, mm

| Power | 500 W | 1000 W | 1500 W | 2000 W | 3500 W | 4000 W | 6000 W | 8000 W |

| Black steel | 6 | 12 | 14 | 18 | 20 | 22 | 24 | 26 |

| Stainless steel | 4 | 6 | 8 | 10 | 12 | 15 | 20 | 25 |

| Aluminum | 3 | 4 | 5 | 6 | 8 | 12 | 16 | 20 |

| Non-ferrous metals | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 |

Technical parameters

| Model: | FLE3015 |

| Working area | 3050*1550 mm |

| Maximum Z Height: | 90 mm |

| X-axis accuracy | ±0.03 mm/min |

| Y-axis accuracy | ±0.03 mm/min |

| Z-axis accuracy | ±0.01 mm/min |

| X-axis repeatability | ±0.02 mm |

| Y-axis repeatability | ±0.02 mm |

| Z-axis repeatability | ±0.005 mm |

| Transmission speed: | up to 80 m/min |

| Acceleration | 1G |

| Maximum table load | 2000 kg |

| Laser head | Raytools BM111 (with autofocus) (Switzerland) |

| Guides | Bosch Rexroth (Germany) |

| Servo motors | Yaskawa 1,3 kW (Y-axis), 0,8 kW (X-axis), Panasonic 0,4 kW (Z-axis) |

| Reducers | planetary, Shimpo (Japan) |

| Power consumption | from 12 kW/h (depending on the source) |

| Protection degree | IP54 |

| Weight | 4500 kg |

| Dimensions | 4610*2941*2078 |

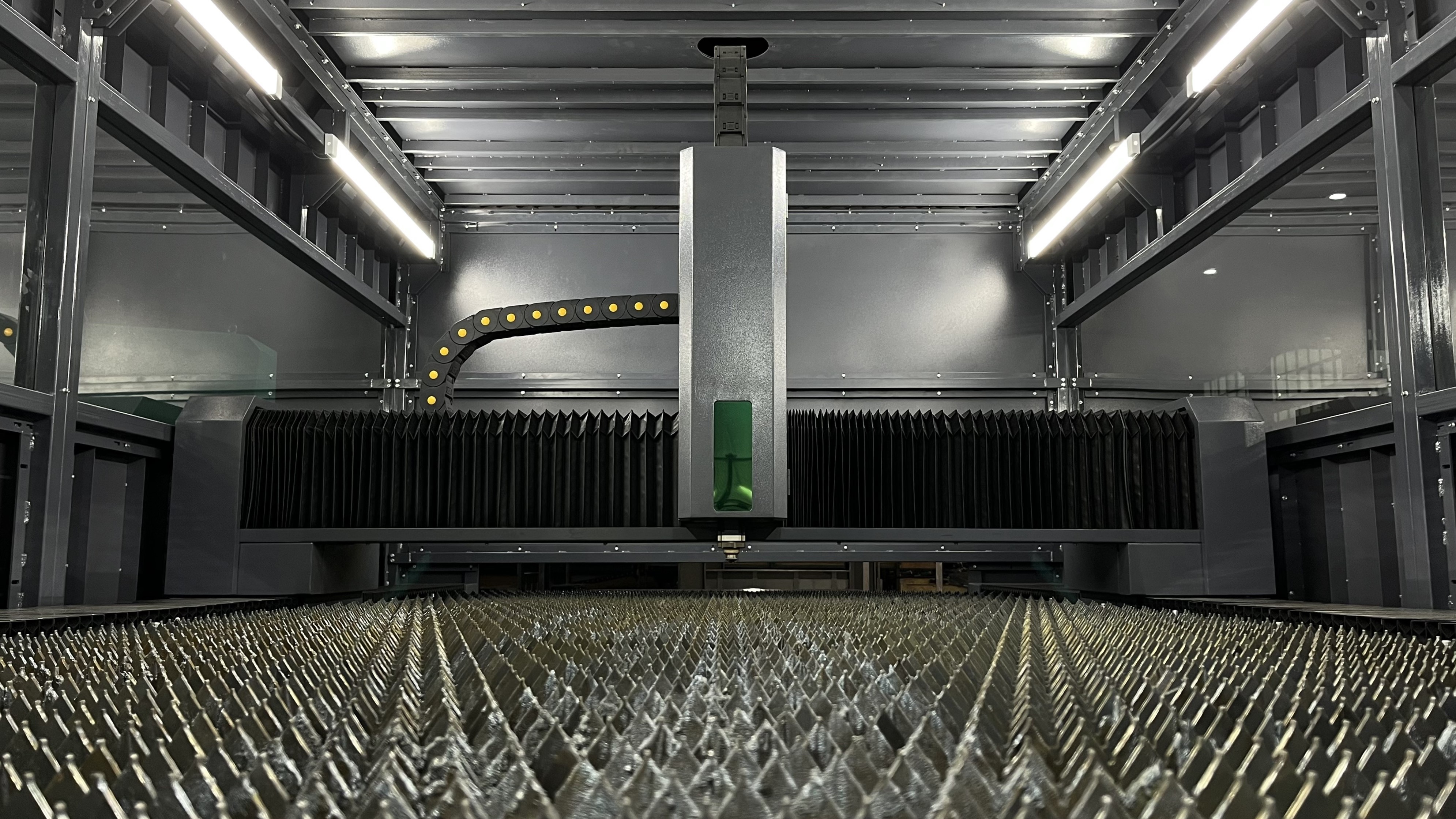

Base

Уникальная тяжелая гибридная сварная станина из секционных стоек и листового углеродистого металла. Более 60% станины из листа металла толщиной 12-20 мм. При производстве станины сперва происходит ее подогрев до температуры 600°C и последующее постепенное охлаждение согласно заранее определенной схеме в течение 24 часов в охлаждающей камере. Дальнейшая обработка производится на современном фрезерном станке длиной 6 метров. Все сварные швы выполняются исключительно в защитной атмосфере. Данная процедура обеспечивает долгий срок службы станка без механических деформаций. Гарантия на станину — 10 лет. Направляющие по оси Y размещены на отфрезерованной до идеала плоскости, что минимизирует любые погрешности при дальнейшей эксплуатации. Также конструкция рамы имеет специальные встроенные вентиляционные каналы на каждой секции, которые в дальнейшем в автоматическом режиме открываются в нужной области во время работы. Продуманная система вентиляции позволяет эффективно отводить продукты горения металла, за пределы помещения или же к системе рекуперации.

Quality checking

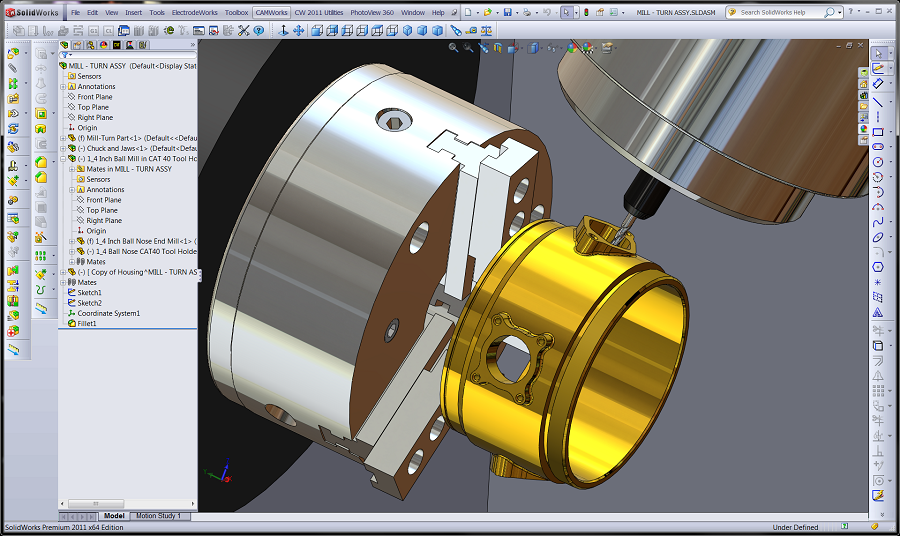

Проектировка, разработка станка и каждого его элемента, а так же дальнейшее тестирование, анализ прочности и ресурса проводится в программе SolidWorks что на выходе дает уже заведомо успешный результат. Абсолютно все плоскости под направляющие и детали станка проходят обработку на немецком фрезерном станке высокого класса точности. Каждый шаг производства лазерного станка и его отдельных элементов тщательно проверяется на соответствие требованиям и чертежам. Применение современного измерительного оборудования при контроле качества позволяет добиться точности перемещения до 0.03 мм на 3 метрах.

Cast aluminum portal

Портал 3-го поколения из специального алюминиевого сплава характеризуется высокой прочностью и легкостью конструкции, а так же способ его производства обеспечивает идеальною ровность поверхности сразу же после изготовления. Портал имеет дополнительные ребра усиления что дает внушительный запас прочности. Несмотря на точность изготовления — плоскости под направляющие все равно фрезеруются. Высокая скорость резки и долговечность станка без деформации. На 50% легче стального.

Laser source

На станках для лазерной порезки метала фирмы MTech используются только оптоволоконные источники MAXPhotonics последних поколений. Данные источники объединяют в себе только лучшие качества и характеристики всех производителей. Высокая мощность, малый вес, высокоэффективная технология преобразования светового потока, и огромный список защитных систем — делают MAXPhotonics самым лучшим и надежным! Мощность лазерного источника подбирается нашими техническими специалистами индивидуально под задачи заказчика.

ПРЕИМУЩЕСТВА:

- высокая мощность с плоским распределением. Степень разбавления обтекающего слоя не менее 3%

- высокая концентрация луча по длине. Отлично подходит для лазерной сварки и стереолитографии плакирования. Быстрый запуск

- опциональный выбор диаметра ядра волоконного ядра. Индивидуальные параметры 800мкм, 1000мкм диапазона серцевины волокна сделает Ваш лазер применимым для большего количества функций, таких как закалка и наплавка.

- QBH или LOE выход. Сильная антибликовая способность с LOE выходом

- высокий уровень вертикальной интеграции. Все ключевые компоненты разрабатываются и производятся на собственном предприятии. Строгий контроль качества, высокая стабильность и надежность

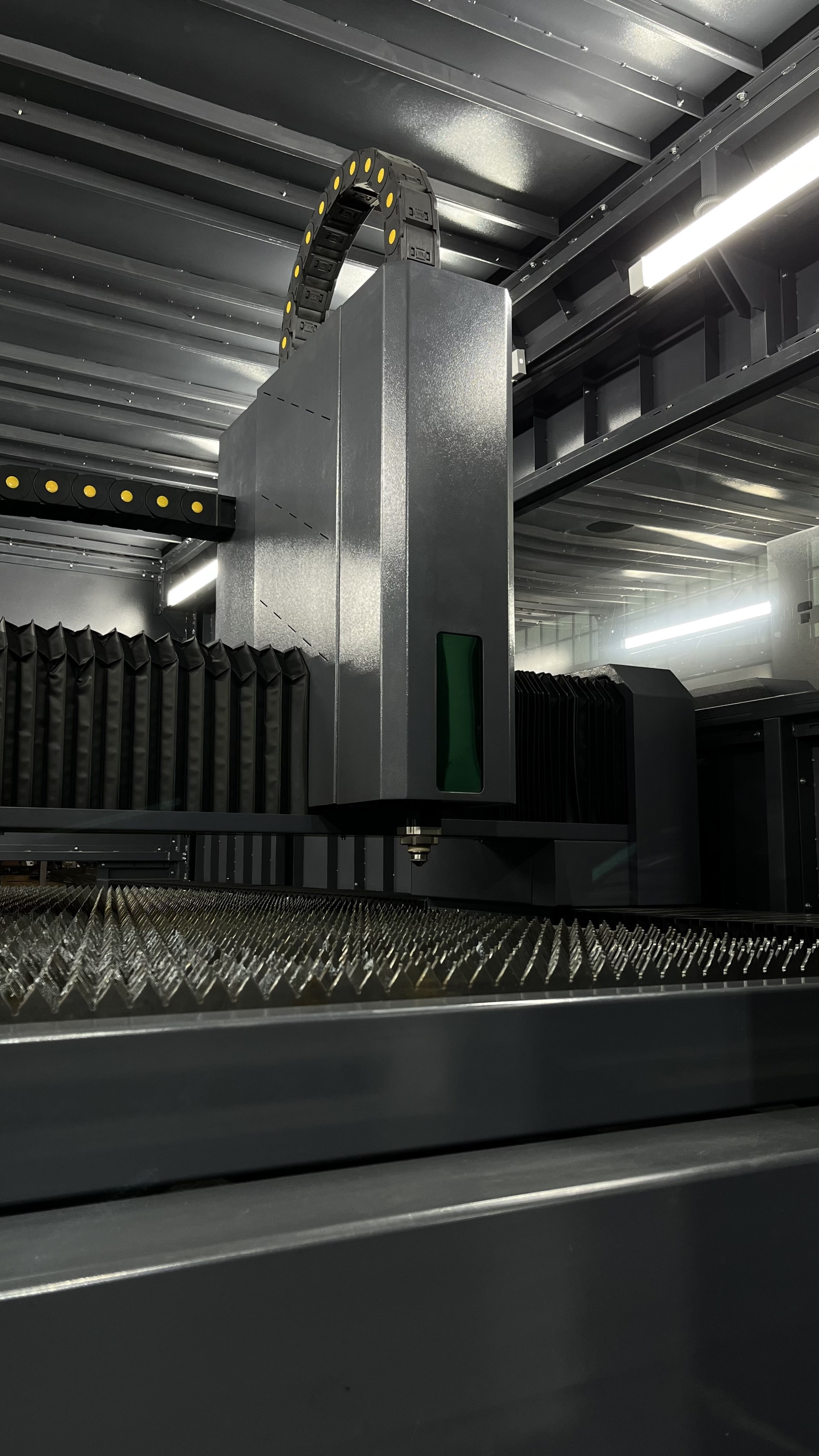

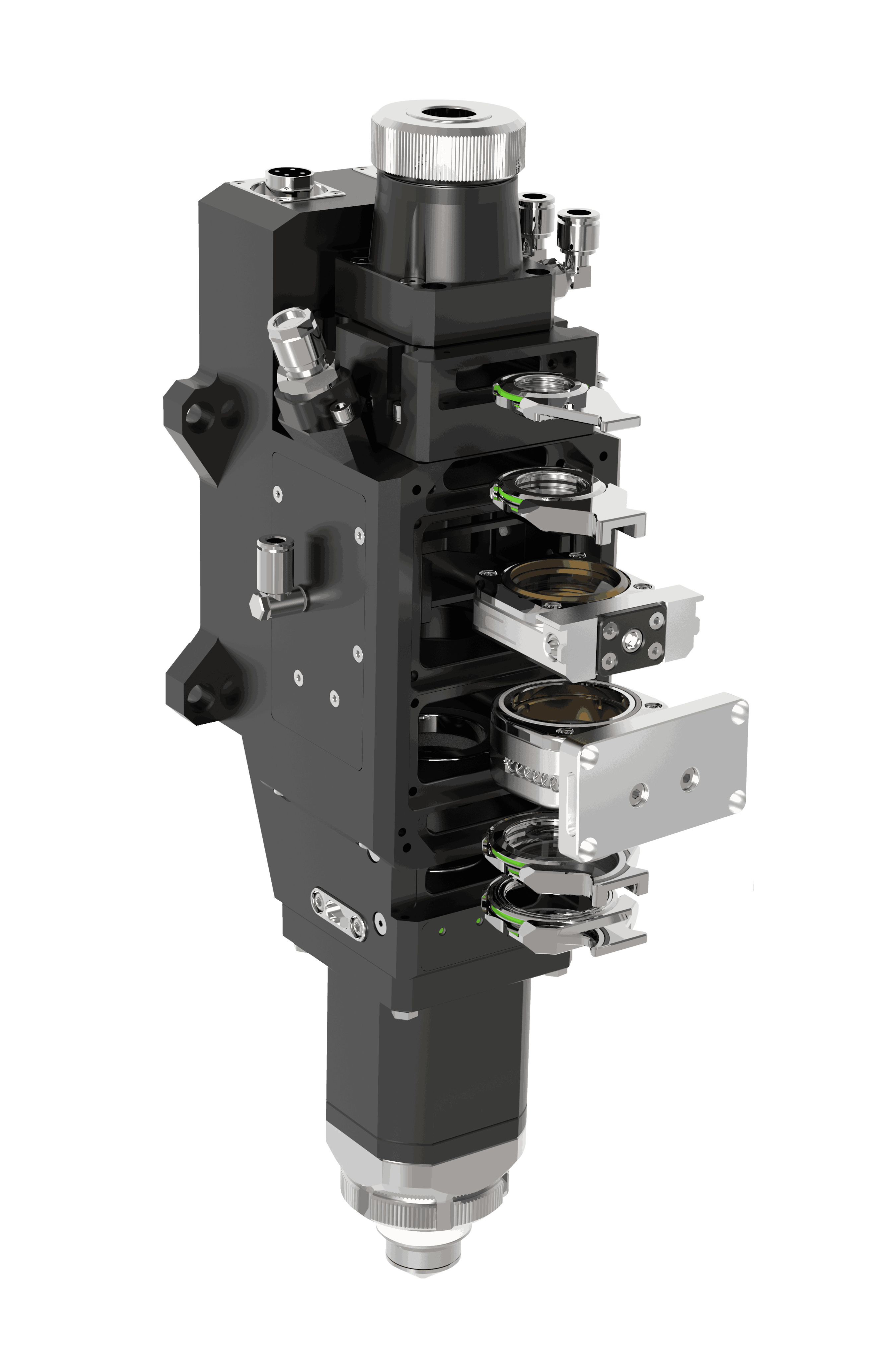

Автоматическая лазерная режущая головка с фокусировкой BOCI

Станки оснащены лазерными режущими головками BOCI (BOCHU), которые являются наилучшим решением на сегодняшний день. Головка спроектирована с учетом всех недостатков моделей конкурентов и внедрением новых разработок, делающих ее идеальным вариантом, который обеспечит долгий срок безотказной работы с лучшими показателями качества резки.

Мониторинг температуры защитной линзы

Лазерная головка BOCI оснащена функцией мониторинга температуры защитной линзы в режиме реального времени во время резки. Если линза загрязняется, система управления немедленно подает сигнал тревоги и останавливает процесс резки. Такой подход эффективно уменьшает дефекты обработки, вызванные загрязнением линзы, и предотвращает дальнейшее повреждение лазерной головки и лазерного источника.

Инновационная конструкция водяного охлаждения для длительной стабильности

Водяное охлаждение лазерных головок BOCI обеспечивает длительную и стабильную производительность резки. BOCI внедрила процесс антикоррозионного покрытия для водяных каналов, предотвращающий коррозию, вызванную длительным использованием. Этот инновационный подход позволяет избежать таких проблем, как засор каналов, что может привести к повреждению лазерной головки или перегреву других оптических компонентов.

Коллиматорная фокусировка

Лазерные головки BOCI используют коллимационную фокусировку, что позволяет регулировать фокусную точку путем точной настройки коллимационной линзы. Это обеспечивает быстрее фокусировку, значительно сокращая время ожидания настройки фокуса. В результате пользователи могут достичь более плавной и непрерывной резки стальных пластин на высокой скорости, что значительно повышает эффективность операций лазерной резки. Эта функция гарантирует, что даже при быстрой обработке система поддерживает оптимальную фокусировку, обеспечивая точные резы с минимальными перерывами.

Защита от столкновений

В реальной эксплуатации лазерных установок столкновение лазерной головки с препятствиями не является редкостью и может привести к дорогостоящему ремонту или необходимости полной замены лазерной головки, что часто требует транспортировки обратно изготовителю и влечет за собой простое. Компания BOCI разработала лазерную головку с инновационной конструкцией защиты от столкновений. При столкновении специально разработанные винты ломаются, защищая другие деликатные компоненты лазерной головки и оптические линзы от повреждений.

Линейные направляющие HIWIN

HIWIN — одни их лучших линейных направляющих в мире. Направляющие Hiwin позволяют перемещать высочайшие нагрузки с минимальными усилиями с высокой жесткостью и, как следствие точностью, которая отвечает требованиям пользователей высокопроизводительных станков и роботов.

Main advantages:

• Super high load capacity in all four main load directions

• High moment load

• Smooth, quiet movement due to the optimal design of the recirculation system of rollers and guide elements

• Mechanical seals fitted as standard

• Optimal design of lubrication channels reduces lubricant consumption to a minimum

Yaskawa servos (Japan)

Применение сервоприводов Yaskawa предлагает точное скоростное позиционирование, плавную безвибрационную работу и быстрый ввод в эксплуатацию. Результат: снижение продолжительности цикла, максимальная производительность, улучшение качества продукции, повышенная износоустойчивость машины, короткое время пуска, низкие суммарные затраты в течение жизненного цикла. Также моторы работают в паре с японскими планетарными редукторами корпорации NIDEC, что дает превосходную точность и внушительную скорость перемещения без дополнительных нагрузок на моторы.