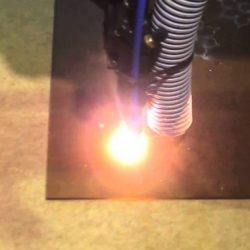

Installing a CNC plasma cutting machine is the last step in choosing equipment. To provide your production with reliable technology, you first need to take into account its needs and functions. According to them, choose a complete set of the machine and its components. When choosing, it is worth considering the volume and frequency of work to be carried out, the specifics of metals, and their sizes. With the help of a CNC plasma machine, materials are cut and processed by an air-plasma arc under the influence of electrical energy. Thin cutting is performed by heating up to 15,000-20,000 ° C. The narrow cutting width (2.5 mm) guarantees material savings as well as concentration on the cutting area. The CNC plasma machine is convenient for both mass production and individual use. As an economical and productive way of cutting metals, plasma cutting is at the same time not inferior to laser cutting and is more often used in the work of mid-level enterprises. Among the main advantages of plasma machines are the following:

1. High Performance.

2. Universality.

3. High cutting quality.

4. Fast material burning.

5. Working with various types of materials.

6. Processing objects and parts of complex shape.

7. No deformation.

The principle of operation of plasma cutting machines allows you to cut metal materials of complex configuration with excellent accuracy.

Where and how to buy a CNC plasma machine. Our team is engaged not only in the delivery of serial production plasma machines, but also in the assembly of machines according to individual orders. Each company, or small production is characterized by its own characteristics, so standard machines do not always satisfy all needs. In order to combine the production functions you need in one machine, it is worth paying attention to bespoke machines. Plasma machines to order: advantages

• Exactly tailored to your production goals with maximum efficiency. At the same time, you will save not only your time, but also production resources.

• Benefit in use. To carry out several different functions, you do not have to buy several machines.

• Custom design also saves money, as two connected machines allow several times more functions with the same resources.

• Possibility of choosing the dimensions of the plasma machine for the space allocated to it in production.

• If necessary, connect additional equipment, be it a controller, compressor, and so on.

Our plasma cutting machines already work effectively in large and small enterprises engaged in various types of activities. We supply plasma machines directly from manufacturers and official distributors without overpricing. Not only legal entities, but also individuals can purchase the necessary equipment with free installation and configuration. You can buy plasma machines from us at competitive prices that meet the requirements of your production. Our consultants will select the equipment in order to fulfill the company's tasks as efficiently as possible. Contact us in any way convenient for you, and we will help you to purchase a high quality machine.

Category Archives: Все статьи

How to choose a laser machine

How to choose a laser (laser engraving) machine? First of all, it is worth determining the necessary characteristics of the device for the types of work you have chosen. The acquisition of a new high-tech machine tool for production is not a sufficient reason. To pay off the equipment, you need to perform work of high complexity on an ongoing basis, as well as the offered service packages.

When you are going to make a new purchase, whether it is a TV, car, phone, or other expensive items and equipment, you are trying to find out the maximum amount of information and familiarize yourself with customer reviews. And only after determining what to look for when buying, you start looking for the model you need, or a complete set of this or that product. The situation is the same with machine tools. CNC laser machines help in processing materials of any complexity - from metal objects, copper, glass to leather, paper, and other "delicate" materials.

When buying a laser machine, you should pay attention to:

- Control systems. CNC laser engraving machines are ideal equipment for processing materials without the use of human resources. They provide remote monitoring via the Internet, or company intranet, according to their needs. Their use does not require preliminary information processing.

- Instruments. You have the opportunity to design a process for instrumental rationalization, but if you are going to use a laser machine to process large batches of objects, you can economically distribute material flows and dispatch. The status of the data on the instruments is transmitted to the controller, which helps to monitor their health.

- Thermal expansion helps ensure high precision machining throughout the shift. Monitoring the propeller cooling process increases the cost of the device, but at the same time protects it from premature wear. A distinctive feature of laser machines is also control by means of DSP-controllers - digital signal processors of multidisciplinary functioning. A state-of-the-art laser machine is designed to meet the latest manufacturing technologies and customer requirements for the finished product. Please note that the efficiency and productivity of a laser machine is 50% dependent on you. To get equipment that meets your wishes and capabilities, you should clearly define its purpose and frequency of use. When purchasing a laser engraving machine from our company, you can count on the consultation of specialists, as well as the development of equipment according to your wishes.

Machines of this type can be divided into three groups:

- Laser machines of compact type and low power (up to 80 watts). Most often they are purchased for small businesses, as well as enterprises engaged in the manufacture of souvenir products.

- Laser cutting machines with a capacity of 80-180 Watts. They are used in working with leather, wood and fabric.

- High-performance machines with high power for large enterprises that are engaged in serial production of products.

We are engaged in the manufacture and delivery of machine tools, according to the wishes of customers, focusing on Western quality standards. Get more information by contacting us by phone and ensure your production with reliable and productive machines.

Laser cutting machine: what to look for

The laser machine is used for engraving, marking, processing and cutting various types of materials (glass, steel, copper, plexiglass, plywood, leather, fabric, etc.) The equipment is widely used in the production of souvenirs, POS materials, and other decorative products. Laser cutting machines are characterized by precision and high performance, along with ease of use. You can achieve whatever results you want - width of cut, precision of the smallest details, transparency of the edge, and so on. When processing materials, the level of thermal and mechanical stress is minimal. Most of the CNC laser machines have the ability to process roll blanks. You can save your money on cutting materials by machine or by hand.

The laser cutting machine can be equipped with rotary devices at your discretion. By lifting and lowering, you can easily handle cylindrical and spherical objects. The system itself converts the coordinates of the movement of the laser head along a certain axis without distorting the final result. BUT! It is worth remembering that CNC laser machine function accurately and reliably only with the correct selection of parameters and settings. The beam acts only in a straight line for a long distance to the first obstacle (in our case, the processed object), and then burns through the material. Moving along a given trajectory, the laser beam creates a pattern according to a given program. You can set "fine settings", for example, the direction of the laser beam along a given axis, the discreteness of drawing curved lines, and so on. Indicators of this type depend on the machine model, software, and also the CNC system. To increase the quality of processing materials, you can contact us for advice, or find the information you need in the instructions.

Advantages of CNC laser machines:

- Non-contact. Using a laser machine, you do not need to fix the workpiece and you can safely work with fragile materials - paper, leather, fabric, as well as rubber (in the manufacture of stamps).

- Processing speed - laser machines work much faster than CNC Routers with a predominant amount of materials.

- Effortless and precise processing of corners, as well as fineness of the cut.

- The quality of processing does not depend on the initial state of the material.

- No solid waste When processing materials, only gas is generated.

- Easy to set up the machine and absolutely no wear on the cutting tool, since all actions are carried out by a laser beam.

- No noise

- Work on the program. For work, you need to set a sketch of a certain complexity, and it will be transferred to the workpiece, and as a result - to the finished product.

Laser machine: price and methods of acquisition

The production of laser machines is developing intensively today and their purchase is a godsend for small and medium-sized businesses, especially if the questions are related to mass production. You can order machines of any complexity and functionality from us. The price will depend on design features, scope of use, technical specifications, and other factors. By contacting us by phone, or in another way convenient for you, you can find out the exact cost of the machine and order the necessary equipment with delivery. We offer favorable terms of cooperation and a comprehensive solution to your production issues.