After much research and testing, RECI launches the new S-series of its third generation laser tubes.

After 10 years in the development of CO2 laser emitters, it's time to upgrade to the third generation.

In the first generation, the metal part of the tube was attached directly to the glass itself, and also used water to cool the mirror. This, of course, had a bad effect on reflectivity and did not guarantee long-term operation. It is also worth considering that when the mirror was cooled, it had different temperatures in the center and along the edges, which led to rather rapid deformation, power reduction and air penetration into the tube.

In the second generation, all these shortcomings were taken into account, and special adjustable bolts were also added to correctly adjust the laser beam. In comparison with the first generation, the performance of the lamps has increased significantly, as well as their operating time. But even here a small problem was identified - the bolts wore out over time, causing a slight misalignment, which led to power losses.

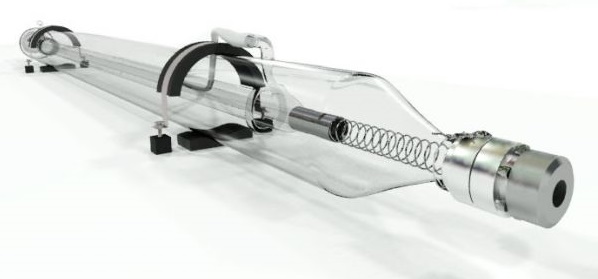

In the new generation of RECI tubes, the possibility of self-adjustment was removed, and all metal parts are manufactured on high-precision equipment and fastened by direct glass-to-metal fusion. The lamp comes fully configured from the factory and is immediately ready for use. New technologies allow for maximum lamp stability and minimal wear over time.

Here you can buy the newest laser CO2 tubes and high voltage power supplies to them.